“

It’s essential now more than ever to get people into manufacturing and get them trained fast.

Beau Wileman

Factory of the Future Manager

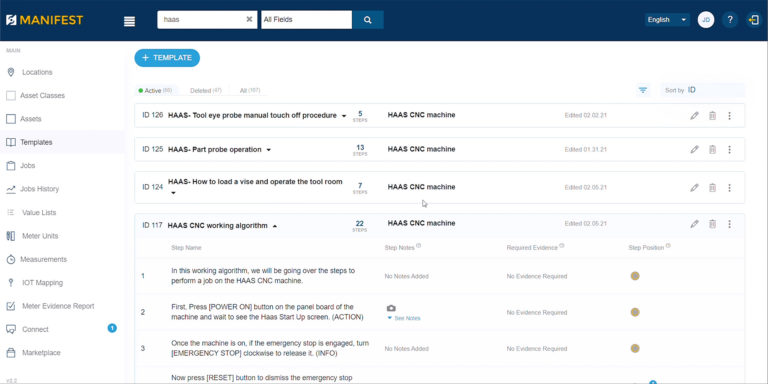

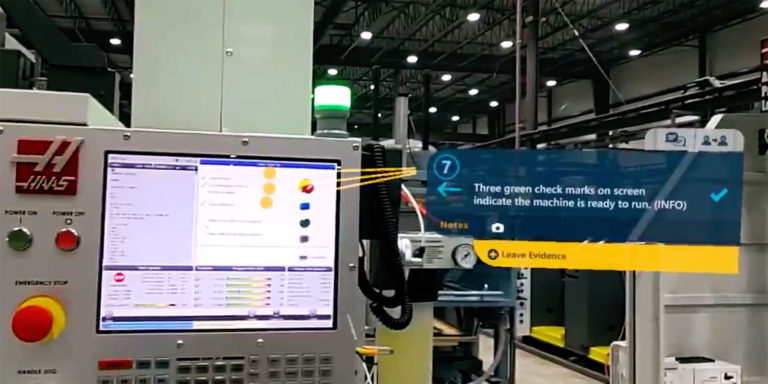

Factory of the Future Manger Beau Wileman discusses how PBC Linear uses augmented reality headsets and iPads with Manifest software to capture expert knowledge and transform that knowledge into work instructions to reduce employee training time from three weeks to three days. PBC Linear is incorporating AR technology into its advanced manufacturing production systems and training programs to benefit their workers and ensure their customers are getting the highest quality parts.

“

My name is Beau Wileman, I work for PBC Linear. I am the Factor of the Future Manager. For augmented reality we use Manifest. With this software we’re able to put a headset on someone the day they start and make sure that they’re getting trained with the templates we want to train them on and we’re able to get them

caught up to speed in as little as three days.

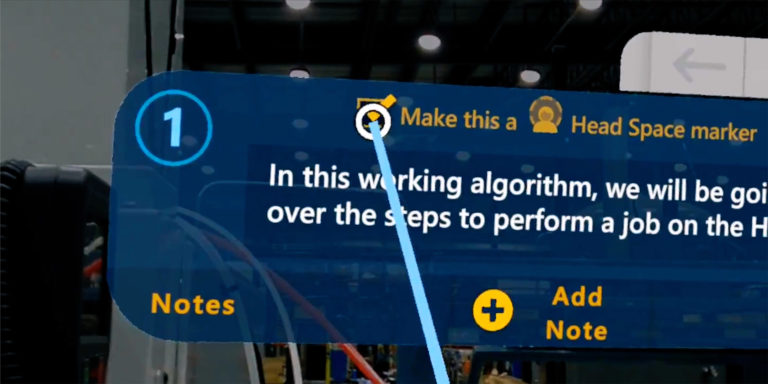

The first thing we do is we record an operator running through the procedures of the machine. Whether it’s start up, tool touch off, blow off, or any sort of quality. We’ll have someone standing behind them recording and asking questions. They then take those recordings and those questions up to either their computer to author the instructions, or in front of the machine they’ll put on a HoloLens or Magic Leap and they’ll start creating those instructions, just as the tool maker operator laid out for them. And within just a few hours they’ll have a virtual reality or augmented reality version of that same training.

We have people that have never done any sort of machining or tooling be able to put on the headset and within a day or two become an expert in a few areas within the field.

If it’s the case where they’ve never worked on it we probably put them through a complete headset training to make sure they go through all the steps and leave evidence, that way we know they’re learning what they should be learning.

If they’re going back to something they’ve trained on previously but haven’t been working on it for a while, we’ll probably give them the iPad so that they can quickly scan in and go through the templates on the tablet interface so that way they can quickly get back to doing their job.

It’s a very scalable software so as our company grows it’s going to be a lot more of a necessity for us to get headsets on people a lot quicker. With the age gap in manufacturing, the skill gap, it’s essential now more than ever to really get more people into manufacturing and get them trained fast so that all that expert knowledge accumulated over careers doesn’t get lost.