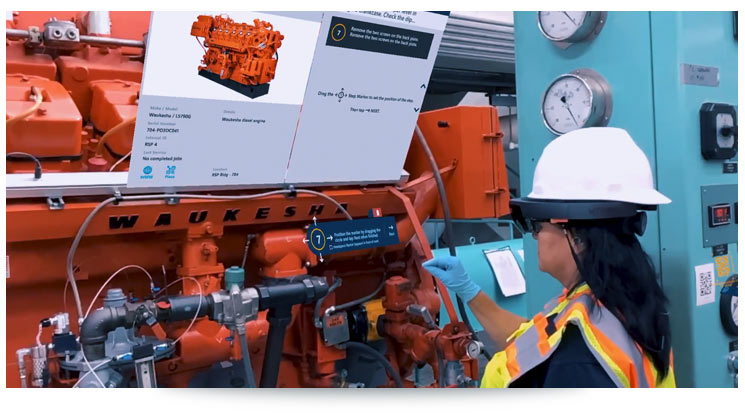

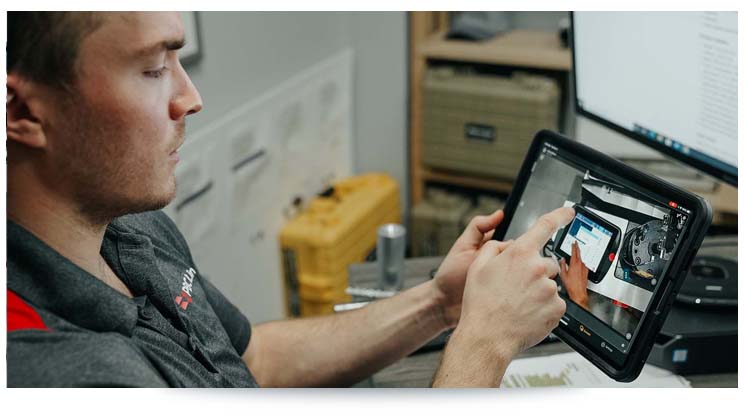

Augmented reality for

manufacturing process

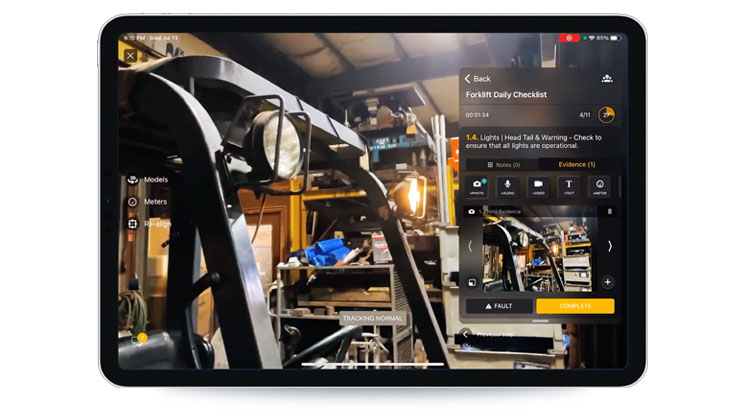

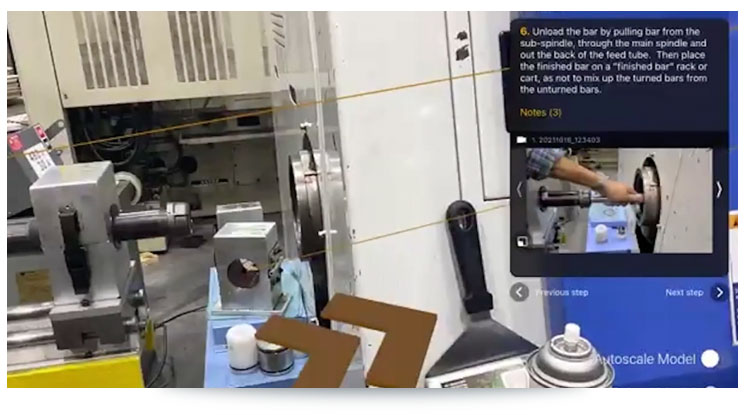

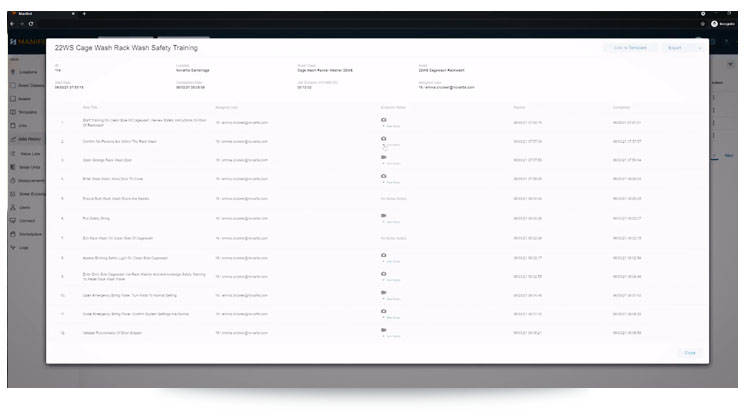

Capture your expert knowledge, before it disappears. Standardize and digitize operational and maintenance manufacturing processes with Manifest® digital work instructions and drive continuous improvements with a complete job management system.